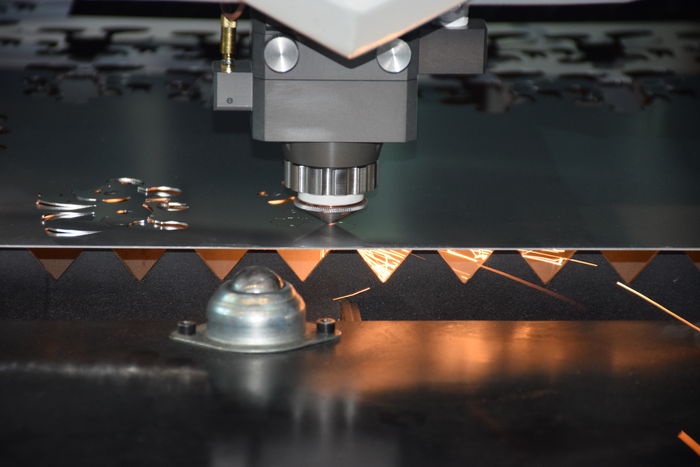

在济南建材市场上,激光切割功率密度对切割速率有很大的影响,透镜焦距的挑选是一个重要问题。光点大小和激光束聚焦后透镜的焦距正相关。激光经短镜头焦距镜片对焦后光斑尺寸不大,聚焦点处功率非常高,这会对原材料切割非常有帮助。

In the Jinan building materials market, laser cutting power density has a significant impact on cutting speed, and the selection of lens focal length is an important issue. The size of the light spot is positively correlated with the focal length of the lens after the laser beam is focused. After focusing with a short lens focal length lens, the size of the laser spot is not large, and the power at the focal point is very high, which is very helpful for cutting raw materials.

镜头焦距与工件表面的位置关系对确保切割品质至关重要。因为聚焦点处功率非常高,在很多情况下,切割时的部位仅仅在材料表面或稍低于表层。在所有钻削环节中,确保聚焦点和工件位置关系不会改变是拥有平稳钻削品质的重要条件。有时候因为制冷不太好,摄像镜头能被加温,造成镜头焦距的改变,因此需要及时纠正镜头焦距部位。

The relationship between the focal length of the lens and the position of the workpiece surface is crucial for ensuring cutting quality. Because the power at the focal point is very high, in many cases, the cutting area is only on the surface of the material or slightly below the surface. Ensuring that the relationship between the focal point and the workpiece position does not change is an important condition for achieving stable drilling quality in all drilling processes. Sometimes, due to poor cooling, the camera lens can be heated, causing changes in the focal length of the lens. Therefore, it is necessary to promptly correct the focal length of the lens.

在大部分运用中,光线聚焦点被调整至喷头的下方。喷头与材料表面之间的距离一般在1.5mm前后。一般来说,原材料切割需要协助汽体。难题主要包括协助气体类型和工作压力。一般情况下,协助气体喷涌方向和激光的喷出方位同样,以保障镜片不受污染,并吹跑切割区底部炉渣。针对非金属材质和其他金属复合材料,用压缩气体或稀有气体消除熔融和蒸发的原材料,与此同时抑止切割区域内的过多点燃。

In most applications, the focus of light is adjusted below the nozzle. The distance between the nozzle and the material surface is generally around 1.5mm. Generally speaking, the cutting of raw materials requires assistance with the vapor body. The main challenges include assisting with gas types and working pressure. In general, the direction of assisting gas injection is the same as the direction of laser injection to ensure that the lens is not contaminated and to blow away the slag at the bottom of the cutting area. For non-metallic materials and other metal composite materials, use compressed gas or rare gas to eliminate melting and evaporation of raw materials, while suppressing excessive ignition in the cutting area.

对于大部分金属激光切割,活性气体(但凡是O2)与钢水产生空气氧化化学反应,可让切割速率提升1/3-1/2。在确保协助汽体前提下,空气压力是一个非常重要的要素。快速切割薄料时,需要锋面气旋,以避免创口反面粘渣(粘到产品工件里的热渣也会损伤切割边沿)。当原材料薄厚提升或切割速率缓减时,应适当调整标准气压。为了避免塑胶刀口起霜,要用相对较低的标准气压切割。

For most metal laser cutting, the active gas (usually O2) reacts with molten steel to form an air oxidation chemical reaction, which can increase the cutting rate by 1/3-1/2. Air pressure is a very important factor in ensuring the assistance of the steam body. When cutting thin materials quickly, a frontal cyclone is required to avoid slag sticking on the opposite side of the wound (hot slag sticking to the product workpiece can also damage the cutting edge). When the thickness of raw materials increases or the cutting rate slows down, the standard air pressure should be adjusted appropriately. To avoid frost on the plastic cutting edge, a relatively low standard air pressure should be used for cutting.

总之,济南激光切割的实践活动说明,其倍率等问题以及纯净度对切割品质有明显直接影响。我们在切割过程中要时刻注意,才能保障不锈钢品质。

版权声明:文章来源于www.jnrqbxg.com/jszc/506.html,转载请注明出处!

下一篇:济南激光切割的激光喷嘴如何维护